Diesel Engine Winterisation

Mostly all of the sailing boat customers I come across, like to have their beloved boats in the water as much as possible! Which means they will only come ashore for a few weeks to get the essential below the water line work done. So I’m going to take you though some simple steps to keep your diesel engine safe from the below freezing temperatures we often encounter during the winter months.

When our boats have had that last fun filled day, or maybe even weeks out on the open ocean, we naturally want them to remain in the best condition.

When those cold frosty nights roll in and we are tucked away in our warm houses moisture outside will begin to freeze, and when water freezes, it also expands which can exert quite a lot of force.

We know that raw water is mainly filling out exhaust manifolds and water jackets, with no where to go. The last thing anyone wants are these to begin to freeze solid and crack anywhere its holding. Quite a common occurrence in the UK.

On my other page about Inboard Petrol Engine Winterisation I wrote about how brackish water, because it is a mixture of salt and freshwater freezes quickly and easily unlike salt water which takes longer.

Do take a moment to read the other guide where I discuss what anodes are best for this situation.

So now we know what it can potentially cause. Were are going to want to prevent this from happening.

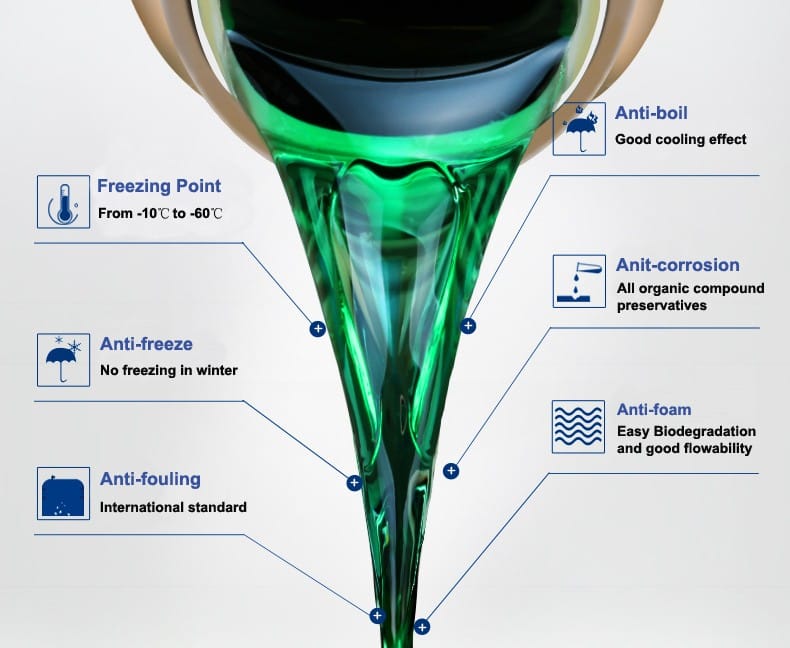

You’re going to want to purchase a 5ltr bottle of ready mixed antifreeze. Be sure not to use individual 1ltr bottles as I like the flow into the engine as consistent as possible, with no intermittency so we are sure to fill the engine evenly with the protective liquid.

Firstly, make sure the engine inlet seacock is CLOSED. This is essential so no risk of flooding occurs. During normal operation its important it should be open but right now we want it closed.

Most engines will have a sea strainer bypassing the inlet. this makes the procedure much easier, I’ll discuss what to do if you don’t have one of these further on.

Remove the strainer lid, this will leave you with easy access to the raw water supply into the engine.

It is much easier to have someone present to switch the engine on, then switch off when the time is needed. But if not, time to get your running shoes on, as you’ll be dashing back and forth from the helm and strainer!

As you switch the engine on, you will notice all the sitting water will drain from the strainer, at this point we want to continually pour the antifreeze into the strainer at a quick rate, as that impeller will want as much as possible and quick! As you will notice.

Continue to do this process until the liquid is visible from the exhaust outlet on the boat. If a strainer is not present, then you can carefully remove the inlet hose from the seacock (remember, close first) and place the pipe inside the antifreeze container, the impeller pump will do the rest.

After that, pop the lid back on the strainer with a little grease on the seal, or if removed pipe, place back on seacock fitting with sealant and TWO RETAINING CLIPS!, now your engine is full to the brim, with anti freezing liquid. Hurrah!!

With petrol engines, its so vital that the compression rings are lubricated in the cylinder as petrol is a solvent and offers little lubrication to engine components. Whereas with diesel the fuel itself does a fantastic job of taking care of this for us, so its unlikely salt corrosion will appear and cause sticky rings after being sat for a while. Great news for the diesel users!

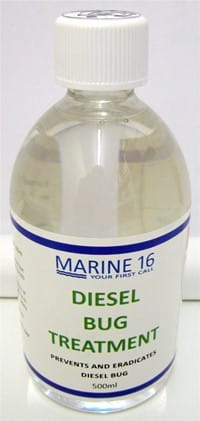

However, when moisture enters the diesel tanks it can cause a bacteria we call diesel bug, a thick black presents will cause chaos with your injector pump, injectors and all filters, nightmare!

This can be preventable, and a good time to get this sorted is while the winterisation is being carried out, as this is the longest the diesel will sit without movement.

Most chandlers will sell a anti diesel bug formula that can be simply added to the fuel tank and let run though the system, this will keep the systems fresh of the ‘BUG’.

A nice coat of quicksilver corrosion guard over the engine will also protect the engine from the salted air.

So now you know your engine is protected from the harsh winter, make sure your batteries are on a trickle charge or otherwise disconnected.

Then when the time comes to use the boat again put something under the exhaust to catch the coolant fluid, start the engine and wait until the exhaust fluid runs clear with water again.

Finally make one last check that there are no leaks from the pipes you’ve reconnected to the seawater pump or seacock and you’re good to go!

Enjoy your boating and let us know if you have any questions. Contact us!